Reduced metamerism, neutral black-and-white images, reduced ink consumption, better shadow detail, and deep color saturation are the primary improvements one can expect from updating their profiles right now.

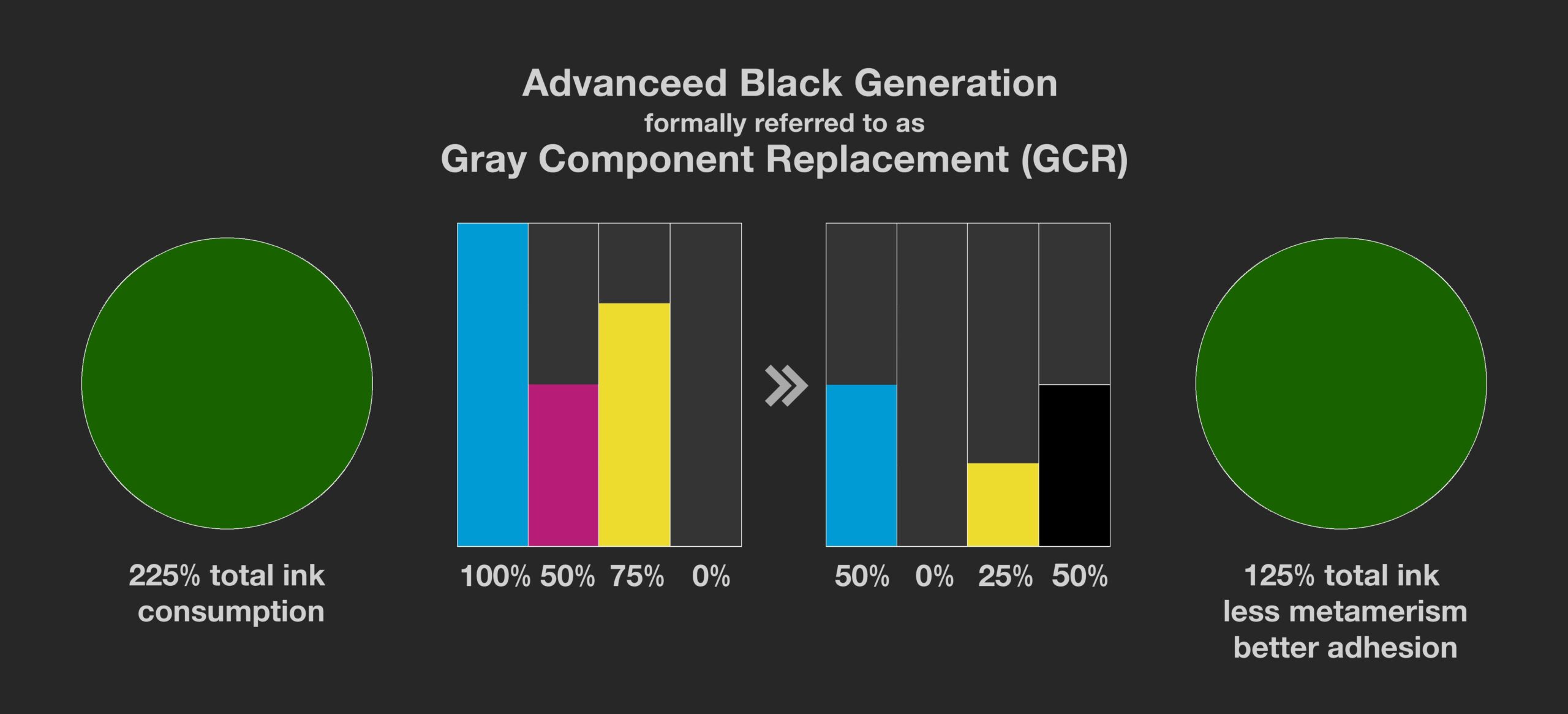

GCR (Grey Component Replacement), or now more broadly referred to as “Black Generation,” has long been a fascination of mine, and I’m always testing to see how far we can go to replace CMY inks with black inks without reducing print quality. For colors like grey, removing the amount of cyan, magenta, and yellow inks and increasing the use of black ink to reproduce these colors results in less ink consumption but, more importantly, less metamerism, which is typically seen when black and white images appear to shift towards magenta or green under different lighting conditions. Metamerism is a big problem for certain printing processes, like dye sublimation, UV curable, solvent and dry toner-based printers.

Applying a strong amount of Black Ink Generation reduces and potentially eliminates the problematic metamerism effect, all while reducing ink consumption. UV print flatten out and lose the embossed effect they are known for. If you apply too much Black Ink Generation, print quality goes down as color saturation is lost, and prints get grainy with too many black dots and not enough of the others to smooth out the appearance of these printer dots. Knowing how to carefully test, evaluate, and dial-in the separation parameters for a process has long been dubbed the “black art” of color management. While confusing at first, it’s really quite empowering to master.

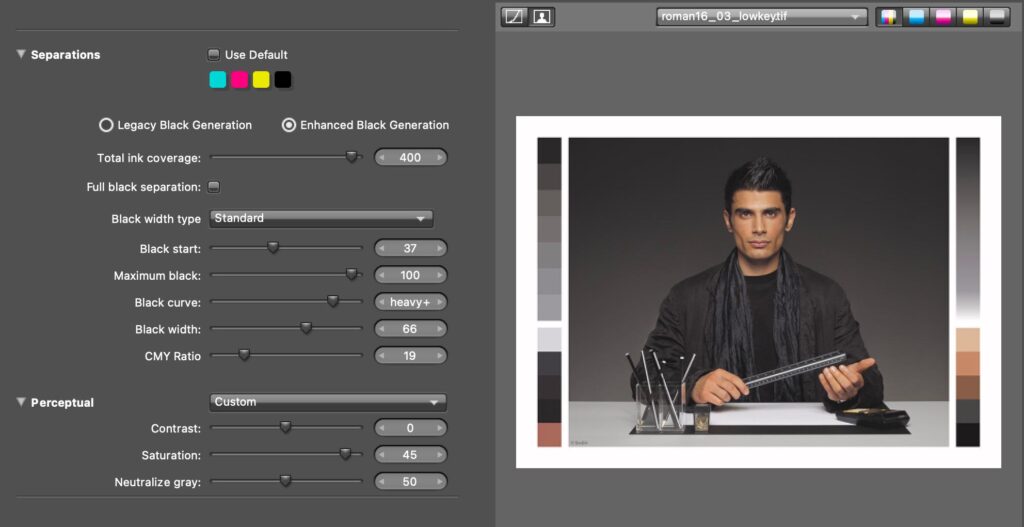

Over the years, there have been a number of eccentric profiling programs that perform exceptionally well in this respect. XRite recently took a deep dive into this and has released an entirely new algorithm for developing Black Ink Generation. This new process comes with excellent controls so that you can tailor it to any process. The new algorithm is computationally intensive and takes ~10x longer to generate the ICC profile. This sort of computationally intensive algorithm would not have been possible 10-20 years ago because it would have taken hours to generate ICC profiles. Developers had to balance the capabilities of their algorithms with the need for speed. XRite felt the time was right to reevaluate this, and the results are fantastic for print quality geeks. I’ve been able to massively reduce metamerism and ink consumption from what I was able to do a short while ago, and surprisingly, UV curable prints flatten out nicely, losing their embossed effect, which also helps with ink adhesion.

If you’re a digital printmaker, I’d like to invite you to use our remote profiling process to refresh your existing profiles so that you might enjoy better print quality, more neutral black and white prints with less/no metamerism, and reduced ink consumption. Dye sublimation, UV curable, and dry toner printers will benefit the most from these improvements. We also make nearly all printer profiles using a large aperture, polarized device that enables better shadow detail, deep color saturation, and better gray balance. If you haven’t updated your profiles recently, the combination of the new hardware and software packs quite a punch in terms of print quality.